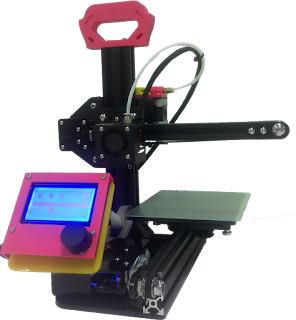

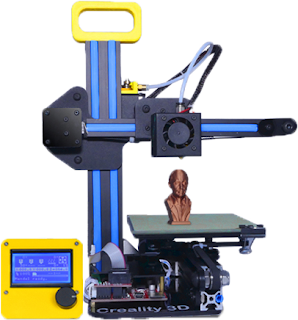

Personal 3D Printer Creality CR-7 / 3D Prototyping (Full Assembled and DIY Set)

Description:

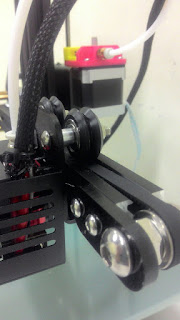

The incredible personal mini 3D printer, CR-7 is now coming. Unique structure design with newest V-slot frame, it brings high accuracy and low noise printing. Line-type bearing and cantilever type: light weight, move smoothly, low noise, fast speed, more accuracy and easy for debugging. The CR-7 is super lightweight, only 3.5KG. With a handle for convenient to carry and potable for user specially children. The working power voltage for CR-7 is only 12V, and can be powered by Uninterruptible Power Supply (UPS). There is no pre-heating requirement for the printing platform and the nozzle is covered, these features reduce the scald danger and safe to be used by children. It come with a LCD control screen that shows the real-time printing status. User can adjust the printing speed, nozzle temperature and so on. The LCD screen and motherboard is pluggable, very easy for DIY and using, you can finish the assembly in 1 hour.

Creality CR-7 can print PLA, Wood-like Material and Flexible Rubber. It also have SD Card to support offline printing. With its portable body, you can enjoy the 3D printing On-The-Go, can be used anytime, anywhere. Creality CR-7 is perfect for DIY amateur, artistic design, architectural design, education, 3D photo studio, etc. Transform a small desk in your home or classroom into an exciting creativity centre.

Features:

· Easy and affordable 3D printing. Designed for entertaining and education.

· Unique structure design, smooth and stable motion with newest V slot frame.

· High printing speed with high printing resolution.

· Light weight, only 3.5kg and portable personal 3D printer.

· Safe for children, working voltage only 12V, no heating bed, covered nozzle.

· LCD graphical display and user-friendly interface.

· Support various type and colour of filament.

Specifications:

Machine Dimension

|

310(L) x280(W) x320(H) mm

|

Weight

|

3.5kg

|

Print Volume

|

130 x 150 x 100mm

|

Printer Speed

|

50 – 120mm/s (Adjustable)

|

Compatible Filament

|

PLA, Flexible Rubber (PLA) and Wood-Like Materials

|

Filament Diameter

|

1.75mm

|

Software Support

|

Cura / Repetier-Host

|

Operating Windows

|

Win10/8/7/XP/Vista

|

Layer Accuracy

|

0.05 – 0.4mm (Adjustable)

|

File Type

|

STL / OBJ / JPG / PNG

|

Power Supply

|

12V

|

Printing Method

|

Online / Offline Printing

|

Operating Ambient Temp.

|

20°C – 35°C

|

Operating Relative Humidity

|

20% – 50%

|

Package included:

1. Creality CR7 3D Printer ( full assembled set) (1 months warranty) x1

2. 1kg PLA filament x1

3. 8GB SD card x1

4. SD card reader x1

5. Tools (as shown below) x1

Make your pre-order today to get more discount!

Contact Now: Mr. Kayson 012-7803379